A man by the name of Frédéric Robert can be credited for the creation of the Seamaster 600 or ‘Ploprof’ from ‘Plongeur Professionel’, among a number of other ‘Professional’ models like the ‘Omega Flightmaster’ and ‘Seamaster 120 Big Blue’. He joined Omega in 1967 as an advisor after successfully growing the company ‘Aquastar’, which he founded and owned. A ‘Marine Unit’ was set up at Omega under his stewardship, and by 1968, the framework for the ‘Ploprof’ as we know today was established in Robert’s unit (1,8).

Concept Development

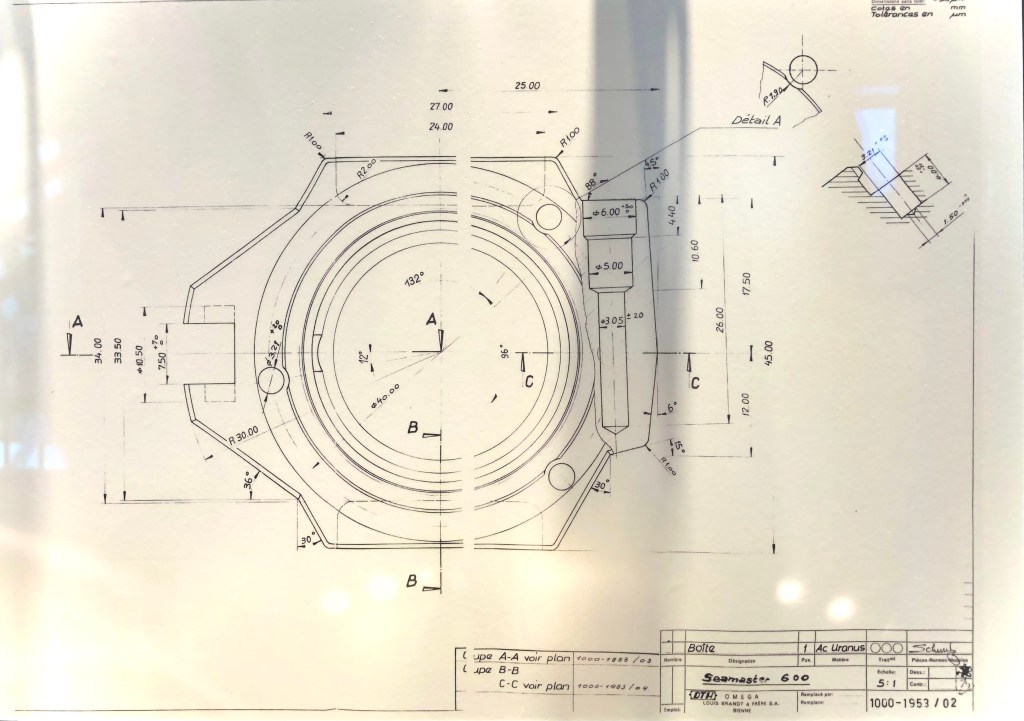

By 1967, the first patent was filed by Omega (#CH480680), and it outlined a rather unconventional case design. The case was fashioned from a single block of steel, which allowed for superior structural integrity and minimal points for water ingress to occur. By doing so, the more pressure is applied to the crystal as the watch goes deeper, the tighter the seal becomes as it compresses the gaskets (1).

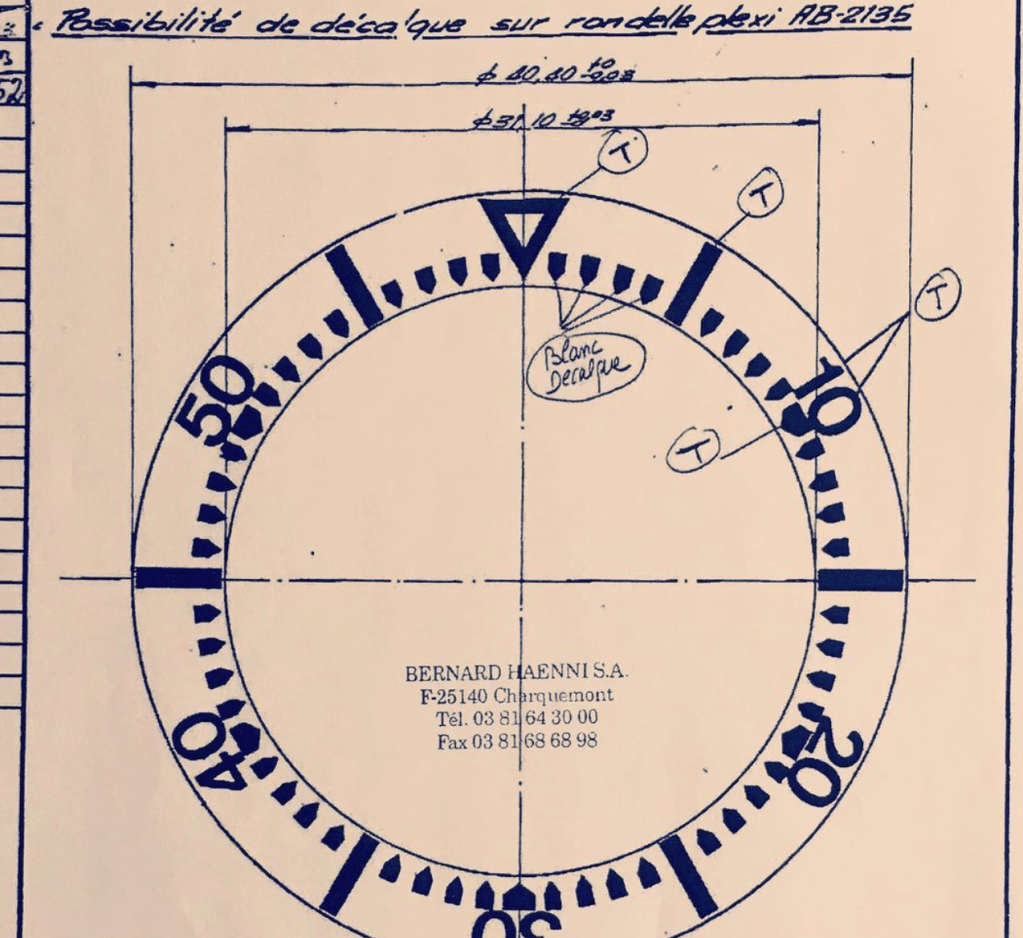

The ‘Seamaster 1000’ employed the same top-loading design, but it lacks the bezel-locking mechanism and crown assembly unique to the ‘Seamaster 600’. The locking mechanism is housed on the right side of the case, and the crown on the left. The ‘Ploprof’ is designed for right-handed divers to be able to operate the locking mechanism – which typically sees more use than a crown – with one hand, and without taking the watch off. To turn the bezel without depressing the red plastic button is not possible. The bezel advancing unintentionally being a problem with most dive watch designs of the period. The red plastic button takes a significant amount of force to push down, and that unlocks the bezel to be able to be turned freely bi-directionally (1).

The crown works differently than in all other watches. The protruding shape of the case on the left side acts as a crown guard, and the square crown is recessed flush into the case. To release it, one has to turn a fluted nut. When the crown is not used, the case features one contiguous line that doesn’t snag on anything and helps prevent any damage to the crown or stem. The crown locking mechanism, when seated properly, forms a seal that’s impervious to any liquid or gas ingress in a way that was simply more secure than other systems (1).

Prototyping

The Case

The case design was established 1967, and initially the cases were also officially tested in ‘inverted’ configuration. The case marks are always upright and there are case versions where the case is configured with the crown on the right and the bezel release button on the bottom left corner (9).

It was assumed for a long time, that Seamaster 600 in latter, inverted’ configuration would have been wrongly assembled, using an alternative date disc. As the dial can be mounted also in 180° position, the case ends up upside-down. Most Seamaster 600 in this ‘inverted’ configuration are indeed mounted the wrong way around, as it is difficult to source correct date discs. However, Marco Richon’s research has shown, that these inverted cases were part of the development. Richon’s research is confirmed by Michel Geiger, a former ‘prototypist’ in Omega’s R & D department working on diving watches. Geiger remembered well, that the very first series of this model, for which he had fashioned the cases in brass, were of the ‘inverted’ type, with a crown at three o’clock and a red push-piece at the bottom left. He no longer remembered, whether there were 300 or 500 pieces made, but confirms that they had been given to to professional divers from Comex (Compagnie d’expertises maritimes) for wear testing (9).

After testing, the professional divers had criticised the protruding volume of the crown and its protective slot, which hampered their wrist movements and tended to tear their rubber suit. Hence the decision to turn the case 180°, so that the crown would be positioned at nine o’clock (9).

Once the orientation of the case established with the crown on the left, earlier, experimental versions show thinner back plates, which allowed the triangular shaped case maker stamp of ‘Schmitz Frères’ to shine through (2). This peculiarity has been corrected for later versions. The case of the second-earliest prototypes are not or only slightly chamfered and show a ‘low grain’ finish (7).

It has been confirmed by the thorough research of @t_solo_t, that early on titanium prototypes of the Ploprof 1 were developed by case maker ‘Schmitz Frères’. About 10 are thought to exist. At the time, titanium had just made its way into commercial and military aircraft. Titanium was in such short supply that the U.S. government had to set up shell corporations and secretly buy it from Russia to produce the Lockheed SR-71 Blackbird reconnaissance aircraft (which was highly classified as well). A similar strategy was used by Omega which pretended to sell titanium cased Seamaster 600 models in Finland to justify the need for titanium when sourcing the material from Russia. Omega even published fake advertisements in Finland to cover the ruse (7).

The used titanium for the cases is of T2 type, which is as corrosion resistant as platinum. This feature explains also, why such titanium cased versions were tested during the Janus II project in deep ocean saltwater. Moreover, @_tsolo_t has compared the measurements of the titanium version to the steel prototypes and has found that the titanium versions are slightly bigger in size and that they show a distinct ‘lip’ underneath the bezel. Confirming the fact, that these titanium versions were developed as very early versions, the indexing of the bezel is provided by spring loaded studs (see explanation below) (7).

Interestingly, the testing of titanium cased prototypes for professional diving, timely coincides with the testing of titanium cased Speedmaster’s (Alaska I) for the use in space. Thus, as for the development of the Seamaster 1000, where developmental steps concerning the design of the case (Mark II case design for space use (Alaska I) vs. Mark II case design for professional divers) or the testing of the compatibility of battery powered movements (Alaska III vs. tuning fork and quartz prototypes for professional diving).

All these parallels imply, that the engineers working on the two respective projects (use in space and for professional diving) exchanged expertise and tried to test new hypotheses in both projects simultaneously.

According to production notes from Omega, the type of steel used was dubbed ‘Uranus steel’ by the French manufacturer that supplied the metal. This variety of steel featured the addition of molybdenum to help resist the corrosion caused by acids. Omega settled on this specific alloy after studying the effects of underwater welding in saltwater on stainless steel watches. Today, this specific type of steel is often referred to as ‘904L stainless steel’. The vessels and tools that COMEX (see below) built were often fashioned out of 904 steel (1).

Another feature of some ‘Seamaster 600’ prototypes is the engraving on the case back and/or side of the case. Some prototypes are marked with the internal prototype code 4-0xx or 4-1xx in addition to the ‘Prototype’ engraving. Please note, that the codes 3-xxx were used for the ‘Seamaster 120 Big Blue’ prototypes and 5-xxx were used for the prototypes of the Seamaster 1000 (7). Some prototypes were engraved with the project name during which they were tested and/or the company name COMEX (see below). Many prototypes feature completely unmarked cases.

Crown, Dial and Bezel

Prototypes feature small differences as compared to the marketed versions. One early feature was a red, acrylic nut against witch the crown was secured. Earlier steel nuts were prone to seizing up with grit. Michel Geiger remembers having to buy toilet brushes with red plastic handles at Migros (a chain of Swiss grocery stores) to obtain the raw material he needed to machine the large push-button on the rotating bezel and the tightening nut on the crown (9).

The acrylic versions should ensure smoother operation, but they would wear down very easily and cause even more problems and thus steel versions were preferred and re-introduced. A rare early but finally unused variant of the steel crown would be painted in red. As seen in the center picture above, the earliest dials (D0) were only marked with ‘Seamaster’ and did not feature the depth rating yet (2).

The early version of the bezel indexing system relied on spring loaded studs, similar to the ones used for the ‘Seamaster 1000’. The marketed version of the ‘Ploprof’ will have bearings for indexing, which will change in size during its evolution.

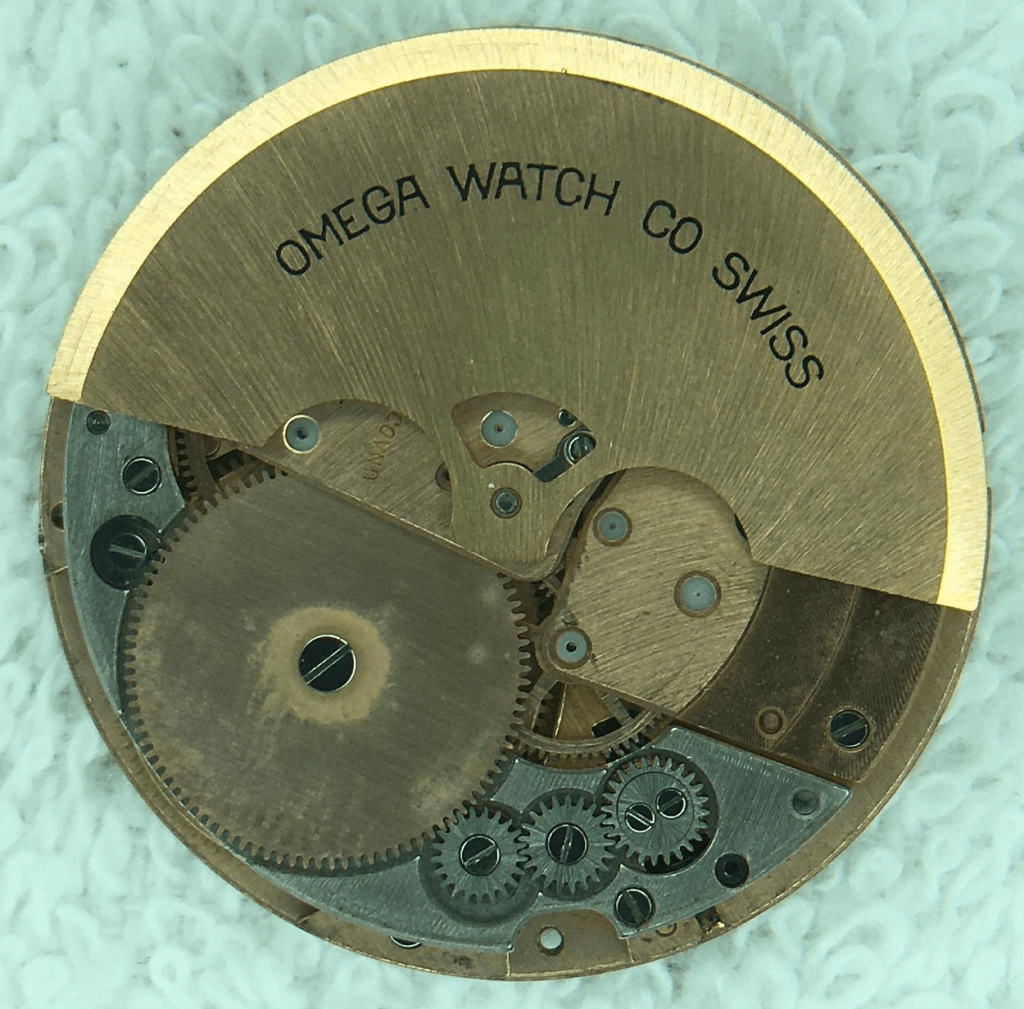

Caliber 1000 Series

Not only the case design was subject to development, also the movement driving the watch would pass several developmental stages before reaching production status. To keep up with the concurrence, Omega needed to update its automatic caliber series 550 by introducing higher beat rate and hacking seconds. Moreover, the new movements would need to be easy to mass produce. Their solution was the introduction of the new cal.: 1000 series in 1968. Very early on cal.: 1000 and 1001 were also used for the ‘Seamaster 600’ prototypes. These prototype movements are unnumbered or numbered with the prototype numbering 0000xxxx. Normally these movements are jeweled (17 jewels), but there are rare, experimental cal.: 1000 versions with nylon bearings instead of jeweling (2).

COMEX et al.; Functional Testing

COMEX (Compagnie Maritime d’Expertises) is a company specialising in engineering and deep diving operations, created in November 1961 by Henri Germain Delauze and ran by him until his passing in 2012. The company is known worldwide for its technology in regard to underwater exploration at great depths. Their line of business includes: hyperbaric testing facilities and oceanographic research ships (Minibex and Janus). COMEX carried out pioneering work in very deep saturation diving. The company experimented with the use of hydrogen in the divers’ breathing gas. This work with heliox and hydreliox gas mixtures started with the project ‘Hydra I’ in 1968 (5).

Omega watches were extensively used and tested during COMEX diving and exploration missions taking place between 1968 – 1970 (2). In September 1970, as part of the testing phase of the ‘Ploprof’, divers Christian Cornillaux, Michel Liogier, and Patrick Cadiou wore the watch during Operation ‘Janus II’. Oil companies Elf/Erap contracted the team of divers working for COMEX to explore and survey the Ajaccio Gulf on the island of Corsica for eight days. The watches were worn for four hours a day in the field at 253m during the operation as part of the testing and development program (1).

Omega sent also a number of prototypes to Ocean Systems Inc. in Tarrytown, NY to test, and the diving research company came back with a statement claiming the Ploprof was more watertight than a submarine. It isn’t stated by what parameters that test was measured (1).

The ‘Seamaster 600’ would be introduced to the public at the 1969 Basel Show and was issued for retail in April 1971 (2). The Seamaster 600 ‘Ploprof’ is indicative of Omega’s design creativity.

Conclusions

Despite the enormous efforts being made for the development of the ‘Professional Seamaster 600’, many professional divers regarded the watch as over-engineered and preferred to use the ‘Seamaster 1000’ instead.

I would like to thank @t_solo_t for sharing his research on these professional diving watches and for allowing me to publish his findings on this platform. For more information about this model and for the presentation of all known iterations, please visit his excellent site.

Ref.:

- Hodinkee

- Omegaploprof

- Perezcope, Picture taken by Alberto Isnardi (@albertoisnardi)

- GQ-Magazine

- Wikipedia

- Dive Into Watches

- Personal communication with @t_solo_t

- Personal communication with Petros Protopapas; Head of Brand Heritage, Omega, Bienne

- SAMO